Overview of Hydraulic Clutch Systems

Hydraulic clutch systems offer a modern twist on traditional mechanical setups, providing smoother operation and ease of use. At their core, these systems utilise hydraulic fluid to transfer pressure from the clutch pedal to the clutch itself. This pressure facilitates clutch engagement and disengagement with minimal effort, making them especially appealing for performance vehicles like the Chevrolet Corvette.

Upgrading to a hydraulic clutch system in a Corvette can significantly enhance the driving experience. One of the most lauded benefits is the improved pedal feel, making it more responsive and easier on the foot. Additionally, hydraulic systems are known for their reliability and reduced maintenance needs.

Also to read : How to Safely Install a Roll Cage in Your Toyota Supra for Ultimate Track Day Protection

Despite the advantages, some drivers harbour misconceptions about hydraulic clutches versus mechanical ones. A typical misunderstanding is that hydraulic systems are more prone to failure due to their complexity. However, modern advancements in hydraulic technology have addressed many of these concerns, ensuring durability and longevity.

Recognising the virtues of a hydraulic clutch can transform your driving journey, offering both a tangible mechanical upgrade and an elevated sense of driving enjoyment in your Corvette.

This might interest you : Transform Your Nissan 350Z: The Complete Adjustable Rear Suspension Kit Upgrade for Superior Track Performance

Tools and Materials Needed

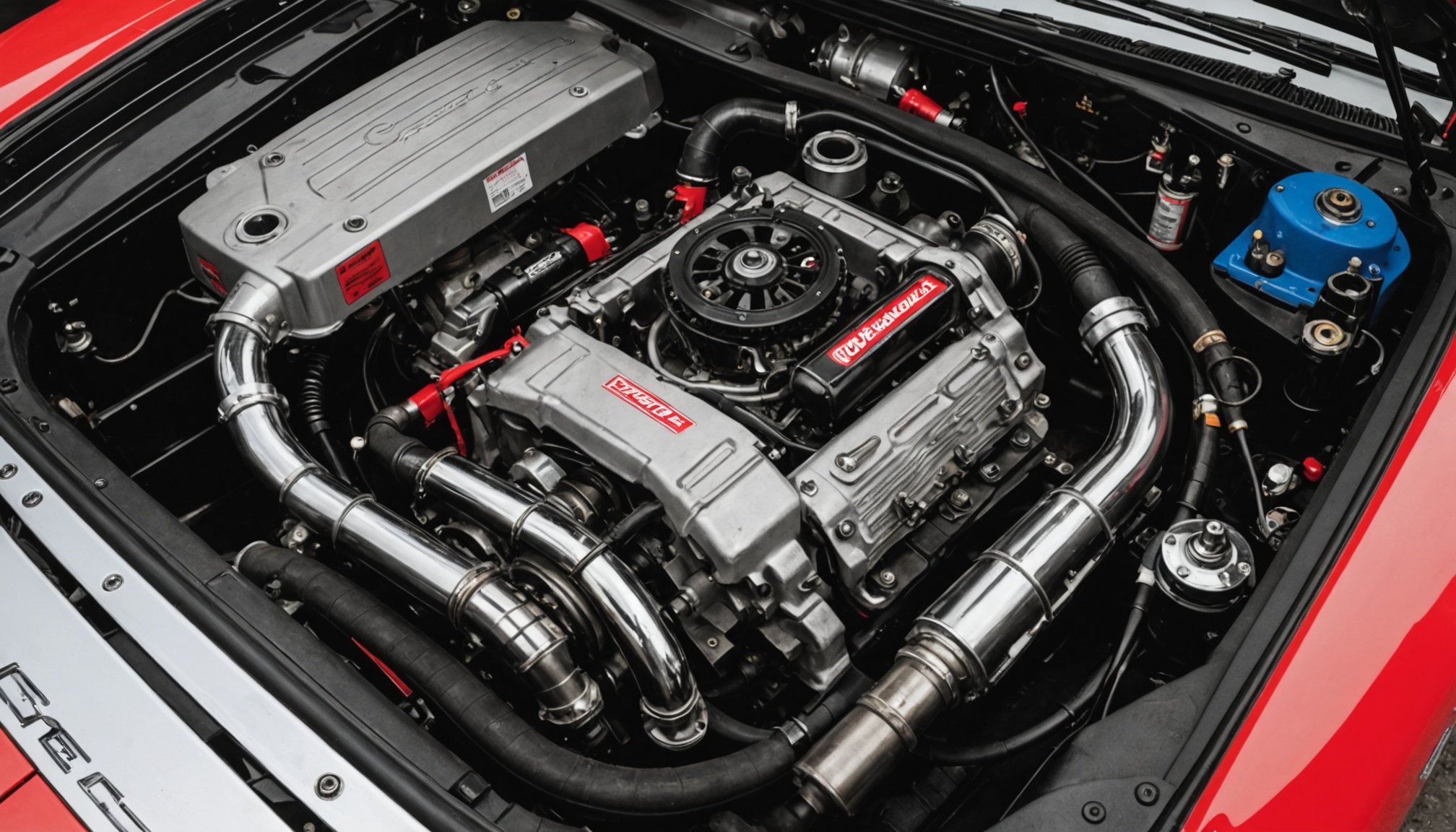

Embarking on a DIY clutch conversion requires the right tools and materials to ensure a seamless process. At the forefront are essential tools for clutch conversion, such as a torque wrench, socket set, and screwdrivers of various sizes. These are critical in handling the intricate parts of a hydraulic clutch installation. A DIY clutch conversion kit often includes vital components like a master cylinder, slave cylinder, and the necessary hydraulic lines.

For a successful conversion, high-quality materials for hydraulic clutch installation are indispensable. Opt for brands known for durability and performance, ensuring your Corvette achieves the optimal pedal feel post-installation. Consider purchasing from reputable suppliers that specialise in automotive parts to source these components and tools.

Tips for sourcing high-quality parts: consult user reviews, join Corvette forums for recommendations, and compare prices. Remember, being informed boosts your chances of a successful installation, enhancing the overall experience. By choosing reliable parts, you mitigate potential challenges down the line, simplifying the maintenance of your hydraulic clutch system.

Step-by-Step Guide to Conversion

Embarking on a hydraulic clutch installation process in your Corvette requires careful planning and execution.

Preparing for Installation

Begin by prioritising safety precautions and ensuring your workspace is clear and well-lit. Safety goggles and gloves are crucial to protect yourself during the process. The initial steps involve disconnecting the original clutch system. Carefully remove each component to avoid any damage, as delicate parts may require reuse.

Installing the Hydraulic Clutch Kit

Proper alignment of the hydraulic components is essential to ensure functional operation. Connect the hydraulic lines and check that all fittings are leak-proof. This step is vital for maintaining the integrity of the system and ensuring no fluid escapes, which could hinder performance. Once connected, adjust the pedal feel and engagement points according to your preference, enhancing your connection to the vehicle.

Final Adjustments and Testing

A thorough system bleed ensures optimal pressure distribution within the new clutch setup. Conduct a pressure check to verify the system operates correctly. Post-installation, perform various tests to ensure the system functions smoothly under different conditions. Address any issues immediately to avoid future complications and enjoy a seamless Corvette conversion guide experience.

Potential Challenges and Solutions

Navigating a hydraulic clutch installation can pose several challenges, but preparing for common pitfalls will smooth the process.

One common issue is hydraulic system leaks. These can often be traced back to improperly connected hydraulic lines or fittings. Carefully tightening connections and using high-quality seals can prevent fluid escape. If leaks persist, double-check your setup and consider professional advice.

Pedal feel inconsistencies might arise from misaligned components. To ensure a consistent and responsive pedal, verify that the master and slave cylinders are properly aligned. Adjusting these components for optimal engagement can significantly enhance the pedal feel.

When tackling troubleshooting during installation, consult resources such as online corvette forums or expert mechanics skilled in modifications. Engaging with these communities can offer practical insights and feedback from enthusiasts who have faced similar challenges.

Addressing these issues promptly will not only improve the installation process but also enhance your overall driving experience. Being well-prepared, resourceful, and willing to seek help when needed can ensure a successful hydraulic clutch installation.

Maintenance and Care for Hydraulic Clutches

Regular attention to hydraulic clutch maintenance is essential to ensure smooth operation and prolong the system’s lifespan. Begin by checking the hydraulic fluid level frequently. Low fluid levels can cause engagement issues and reduced pedal responsiveness. Monitor for any fluid leaks around the master and slave cylinders, as these can indicate seal or component failures.

Routine inspection of the hydraulic lines is also necessary. Look for signs of wear or damage that might lead to leaks. If any deterioration is observed, replace the lines promptly with high-quality options to maintain system integrity.

Pedal feel inconsistencies often signal the need for service. If you notice changes in resistance or engagement points, it may be time to bleed the system to remove trapped air, ensuring optimal pressure consistency. Continuously assess the Corvette pedal feel to catch potential issues early.

To extend the hydraulic clutch system lifespan, avoid excessive riding of the clutch pedal and ensure timely flushing of hydraulic fluid. Adhering to these care tips not only enhances driving performance but also maximises the benefits of hydraulic clutches.

Enhancing Your Driving Experience

Upgrading to a hydraulic clutch delivers significant performance benefits and an improved driving experience. Many Corvette owners report that the new system enhances overall vehicle dynamics. Increased pedal feel and responsiveness are immediate perks. These attributes bolster the connection between driver and machine.

In terms of performance, hydraulic systems offer smoother gear shifts. This can translate into quicker acceleration times and a more pleasurable driving journey. Real-world feedback affirms this, with users expressing satisfaction over more intuitive engagement points.

User testimonials frequently highlight the improved driving experience post-conversion. Enthusiasts praise the ease of operation during intense driving sessions and city commutes alike. Engaging with community opinions can provide further insights into potential enhancements and modifications.

Leveraging community expertise is invaluable as owners share best practices and performance benefits of hydraulic clutches. By exchanging information within forums, you can uncover additional options to refine and boost your Corvette’s performance. The collective knowledge aids in making informed decisions for future modifications, ultimately helping achieve an optimal driving experience.

Review of Available Hydraulic Clutch Kits

Evaluating the best hydraulic clutch kits for a Chevrolet Corvette involves considering key specifications and customer feedback. Kits such as the McLeod and Wilwood are highly recommended for their durability and performance. When selecting a kit, it’s important to consider factors such as compatibility with your specific model, ease of installation, and included components like a master cylinder and hydraulic lines.

Key features to look for include installation instructions, which can dramatically simplify the process. Moreover, high-quality kits often include all necessary hardware, ensuring a seamless upgrade. Pay attention to material quality; kits made from durable materials typically offer enhanced performance and longevity.

For a value comparison, prioritise kits that balance cost with comprehensive features. This could mean choosing a kit that might be marginally more expensive but significantly reduces installation time or offers superior pedal feel. Engage with user forums and reviews to gather insights on the most effective solutions tailored to your driving style and performance expectations. This community-driven knowledge is invaluable in making well-informed decisions that align with your Corvette’s needs.